300KN Concrete bending and press machine

300KN Concrete bending and press machine

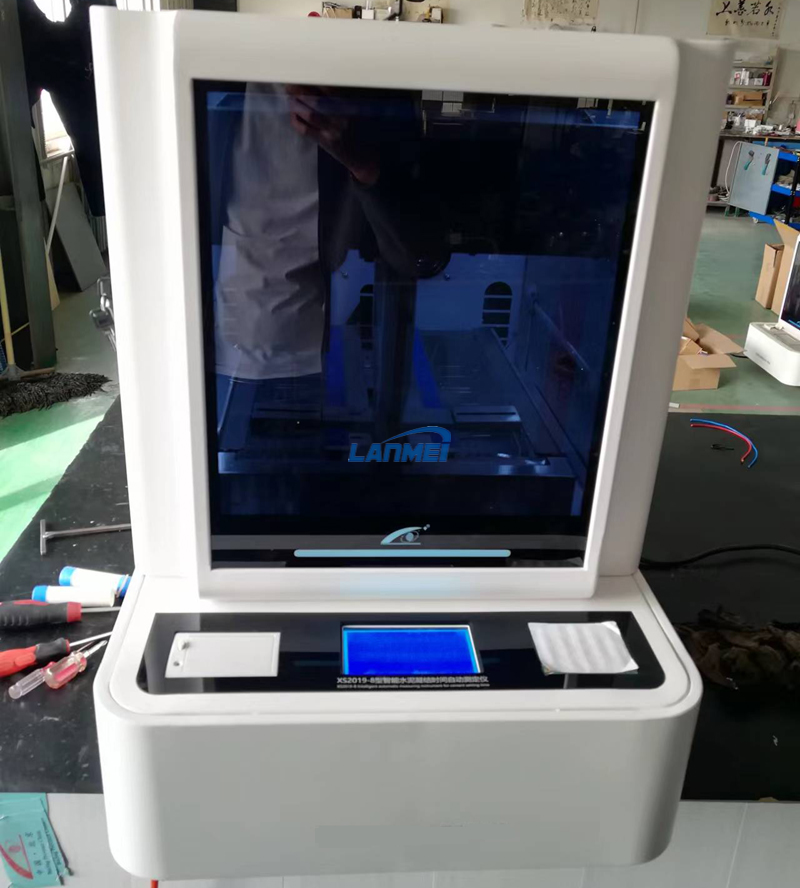

DYE-300S Cement hydraulic Bending and Compression Testing Machine

300KN Concrete Bending Press: Comprehensive Overview

The 300KN Concrete Bending Press is an essential piece of equipment in the construction and civil engineering industries. Designed to test the strength and durability of concrete materials, the machine plays a vital role in ensuring that structures meet safety and quality standards.

With a load capacity of 300 kilonewtons (KN), the machine is able to apply significant forces to concrete samples, allowing engineers and technicians to assess their flexural and compressive strength. The testing process involves placing a concrete sample, typically a beam or cylinder, into the machine. Once positioned, the machine applies a controlled load until the sample breaks, providing valuable data on its performance characteristics.

One of the main advantages of the 300KN Concrete Bending and Pressing Machine is its precision. It is equipped with advanced sensors and a digital display that accurately measure force and deformation, ensuring that the results are reliable and repeatable. This level of precision is essential for engineers who need to make informed decisions based on the material properties of concrete.

Furthermore, the machine is designed to be user-friendly, with intuitive controls and safety mechanisms to protect the operator during testing. Its solid construction ensures longevity and durability, making it a worthwhile investment for laboratories and construction companies.

In addition to testing the primary functions of concrete, the 300KN Concrete Bending and Pressing Machine can also be used for educational purposes. Universities and technical schools often incorporate this equipment into their civil engineering courses to provide students with hands-on experience in materials testing.

In summary, the 300KN Concrete Bending and Pressing Machine is an essential tool for assessing concrete strength and reliability. Its precision, user-friendly design and versatility make it an indispensable asset in professional and educational environments, helping to improve construction technology and safety standards.

The testing machine is used to measure the flexural and compressive strength of cement, mortar, brick, concrete and other building materials.

The machine adopts hydraulic power source drive, electro-hydraulic servo control technology, computer data acquisition and processing, which is composed of four parts: test host, oil source (hydraulic power source), measurement and control system, test equipment, with load, time and test curve dynamic display, timely control function and maximum test force retention function. It is a necessary testing equipment for construction, building materials, highway Bridges and other engineering units.

The testing machine and accessories meet: GB/T2611, GB/T17671, GB/T50081 standard requirements.

Compression / Flexural Resistance:

Maximum test force: 300kN /10kN

Test machine level: Level 0.5

Compressed space: 160mm/ 160mm

Stroke: 80 mm/ 60 mm

Fixed upper pressing plate: Φ108mm /Φ60mm

Ball head type upper pressure plate: Φ170mm/ None

Lower pressure plate: Φ205mm/ None

Mainframe size: 1300×500×1350 mm;

Machine power: 0.75kW (oil pump motor 0.55 kW);

Machine weight: 400kg

350KN Concrete bending and press machine:

2000KN Concrete Press Machine