Cement CO2 Analyzer

- Product Description

CKX-20Apparatus for the determination of Carbon Dioxide content in cement

Detailed introduction of CKX-20 cement carbon dioxide analyzer

working principle:

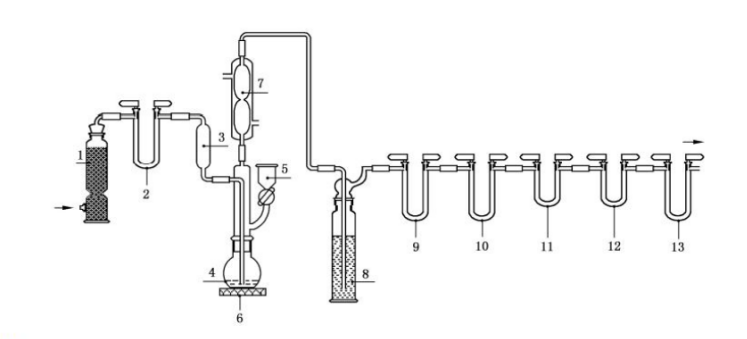

The CKX-20 Cement Carbon Dioxide Analyzer adopts the alkali asbestos absorption gravimetric method. After the cement sample is heated, the phosphoric acid is decomposed, and the carbon dioxide gas released by the decomposition of the phosphate is carried into a series of absorption tubes by the air stream without carbon dioxide. The gas stream entering the system first passes through the absorption tower and U-shaped pipe 2 to remove carbon dioxide from the gas stream. Use concentrated sulfuric acid to remove the moisture in the air stream, and then use a hydrogen sulfide adsorbent to remove the hydrogen sulfide in the air stream. The purified air stream passes through two U-shaped pipes 11 and 12 that can be weighed, and each contains 3/4 alkali asbestos. and 1/4 anhydrous magnesium perchlorate. For gas flow direction, alkali asbestos should be installed before anhydrous magnesium perchlorate. The carbon dioxide in the airflow is absorbed by alkali asbestos and then kept at a constant temperature and weighed.

The main parameters:

1. Carbon dioxide measurement range: ≤44%;

2. Gas flow: 0~250mL/min, adjustable;

3. Heating power: 500W, adjustable;

4. Timing range: 0~100 minutes, adjustable;

5. Ambient temperature: 10~40℃;

6. Input power supply: AC/220V;

7. Display mode: color touch screen;

Structure description

Install a suitable suction pump and a glass rotameter to ensure uniform flow of gas through the unit.

The gas entering the device first passes through the absorption tower 1 containing soda lime or soda asbestos and the U-shaped pipe 2 containing soda asbestos, and the carbon dioxide in the gas is removed. The upper part of the reaction flask 4 is connected with a spherical condenser tube 7 . After the gas passes through the spherical condenser tube 7, it enters the scrubbing bottle 8 containing sulfuric acid, and then passes through the U-shaped tube 9 containing hydrogen sulfide absorbent and the U-shaped tube 10 containing anhydrous magnesium perchlorate, and the hydrogen sulfide and moisture in the gas are removed. remove. Then pass through two U-shapes that can be weighed Pipes 11 and 12 are each filled with 3/4 alkali asbestos and 1/4 anhydrous magnesium perchlorate. For gas flow direction, alkali asbestos should be installed before anhydrous magnesium perchlorate. The U-shaped tubes 11 and 12 are followed by an additional U-shaped tube 13 containing soda lime or soda asbestos to prevent carbon dioxide and moisture in the air from entering the U-shaped tube 12.