Cement fineness negative pressure screen analyzer

Cement fineness negative pressure screen analyzer

Cement Fineness Analysis Using Negative Pressure Screen Analyzer

Cement fineness is a crucial factor in determining the quality and performance of concrete. It refers to the particle size distribution of the cement, which directly impacts the hydration process and the strength of the final product. To accurately measure cement fineness, various methods and instruments are employed, with the negative pressure screen analyzer being one of the most effective tools in the industry.

The negative pressure screen analyzer is a sophisticated instrument designed to assess the fineness of cement particles. It operates on the principle of air permeability, where the specific surface area of the cement is determined by measuring the time taken for a specific volume of air to pass through a prepared bed of cement under specific conditions. This method provides a reliable and precise assessment of the cement fineness, allowing manufacturers to optimize their production processes and ensure the quality of their products.

One of the key advantages of using a negative pressure screen analyzer for cement fineness analysis is its ability to provide real-time data and instant results. This is particularly valuable in a production environment where timely adjustments and quality control are essential. By obtaining immediate feedback on the fineness of the cement, manufacturers can make necessary modifications to their grinding and milling operations, leading to improved efficiency and consistency in the final product.

Furthermore, the negative pressure screen analyzer offers a non-destructive testing method, meaning that the cement sample remains intact after the analysis. This is important for quality assurance purposes, as it allows for further testing and verification if needed. Additionally, the instrument is capable of handling a wide range of cement types and compositions, making it a versatile tool for the industry.

In practical applications, the negative pressure screen analyzer plays a critical role in research and development, as well as in routine quality control procedures. By monitoring the fineness of cement on a regular basis, manufacturers can ensure that their products meet the required specifications and standards. This is particularly important in construction projects where the performance and durability of concrete structures depend on the quality of the cement used.

Moreover, the data obtained from the negative pressure screen analyzer can be used to optimize the grinding process and minimize energy consumption during cement production. By understanding the particle size distribution and specific surface area of the cement, manufacturers can adjust their milling parameters to achieve the desired fineness with greater efficiency. This not only leads to cost savings but also contributes to environmental sustainability by reducing energy usage and emissions.

In conclusion, the negative pressure screen analyzer is an indispensable tool for the cement industry, providing accurate and reliable measurements of cement fineness. Its ability to deliver real-time results, non-destructive testing, and versatility make it a valuable asset for manufacturers seeking to enhance the quality and performance of their products. By leveraging the capabilities of this advanced instrument, cement producers can achieve greater control over their production processes and deliver superior cement products to meet the demands of the construction industry.

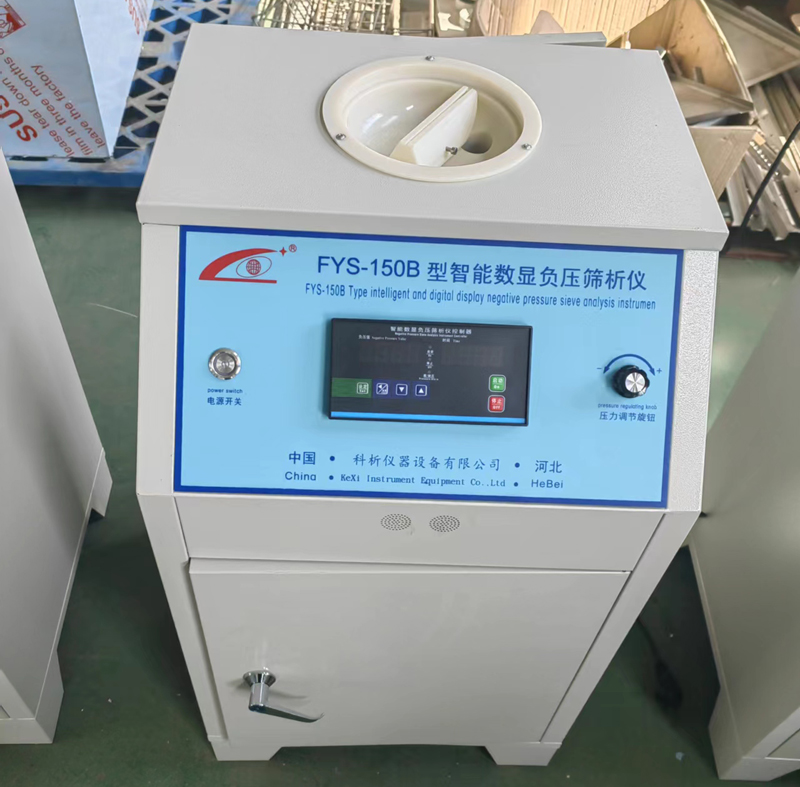

FSY-150B Intelligent Digital Display Negative Pressure Sieve AnalyzerThis product is a special instrument for sieve analysis according to the national standard GB1345-91 “Cement fineness test method 80μm sieve analysis method”, which has the characteristics of simple structure, convenient intelligent processing operation, high accuracy and good repeatability, which can reduce energy consumption .

Technical Parameters:

1. Fineness of sieve analysis test: 80μm,45μm

2. Sieve analysis automatic control time 2min (factory setting)

3. Working negative pressure adjustable range: 0 to -10000pa

4. Measurement accuracy: ± 100pa

5. Resolution: 10pa

6. Working environment: temperature 0-500 ℃ humidity <85% RH

7. Nozzle speed: 30 ± 2r / min

8. Distance between nozzle opening and screen: 2-8mm

9. Add cement sample: 25g

10. Power supply voltage: 220V ± 10%

11. Power consumption: 600W

12. Working noise≤75dB

13.Net weight: 40kg