Motorized flow table for cement mortar

- Product Description

NLB-3 type cement mortar fluidity tester/Motorized flow table for cement mortarThis instrument meets the requirements of JC / T 958-2005 standard and is mainly used for the fluidity test of cement mortar.

Technical Parameters:

1.Total weight of the beating part: 4.35kg ± 0.15kg

2. Falling distance: 10mm ± 0.2mm

3. Vibration frequency: 1 time/ s

4. Working cycle: 25 times

5. Net weight: 21kg

Photo:

Cement fluidity electric jumping table (also known as cement mortar fluidity tester) is used for the fluidity test of the new standard GB/T2419-2005 "Cement mortar fluidity determination method" issued in 2005. It is the only designated standard in this standard. with instruments.

Instructions:

1. Connect the plug to the corresponding hole of the counter, and connect the counter to the power supply. If the jumping table has not been used within 24 hours, first empty jump 25 times in a cycle.

2. Materials and quantities to be weighed in one test: cement 300 grams, standard sand: 750 grams, water: calculated according to the predetermined water-cement ratio. The making of mortar is carried out according to the relevant regulations of GB/G17671.

3. Put the mixed cement mortar into the mold quickly in two layers. The first layer is installed to about two-thirds of the height of the truncated cone. Use a knife to make 5 times in two directions perpendicular to each other, and then use a tamper. The stick is evenly tamped 15 times from edge to center. Then install the second layer of mortar, which is about 20mm higher than the truncated cone round mold. Similarly, use a knife to make 5 times in two directions perpendicular to each other, and then use a tamper to tamper evenly from the edge to the center 10 times. The first layer of tamping depth is tamped to one-half of the height of the mortar, and the second layer is tamped to no more than the surface of the tamped bottom layer. The tamping sequence of the tamping rod is in accordance with the provisions of Article 6.3 in GB/T2419-2005 "Determination of the fluidity of cement mortar".

4. After tamping, remove the mold sleeve, tilt the knife, and wipe off the mortar that is higher than the truncated cone round mold at approximately horizontal angles from the middle to the edge, and wipe off the mortar that falls on the table. Lift the truncated cone upright and gently remove it. Immediately press the "Start" button of the counter to complete a cycle of 25 beats.

5. After the beating is completed, use a vernier caliper with a range of 300mm to measure the expansion diameter of the bottom surface of the rubber sand in two directions perpendicular to each other, calculate the average value, take an integer, and express it in mm. The average value is the fluidity value of cement mortar.

6. The test should be completed within 6 minutes from the start of adding water to the mortar to the end of the diameter measurement.

Operating procedures:

1) Check whether the power supply is complete before use, and perform idling to check whether each control element works normally.

2) Prepare the sample according to the specification, wipe the table top, the inner wall of the test mold, the tamper, etc. with a damp cloth.

3) Put the mixed mortar sample into the test mold in two layers. The height of the first layer is 2/3. Use a knife to draw 5 times in each direction, and use a small knife to draw 10 times and evenly press 10 times. Scrape the test mold.

4) Gently lift the test mold vertically, start the jumping table, and complete 30 jumps within 30±1s.

5) After the beating is completed, use calipers to measure the diameter of the bottom surface of the mortar and the diameter in the vertical direction, and the average value is calculated as the fluidity of the cement mortar with this amount of water. The test must be completed within 5 minutes.

6) Regularly maintain and clean all instrument components every six months.

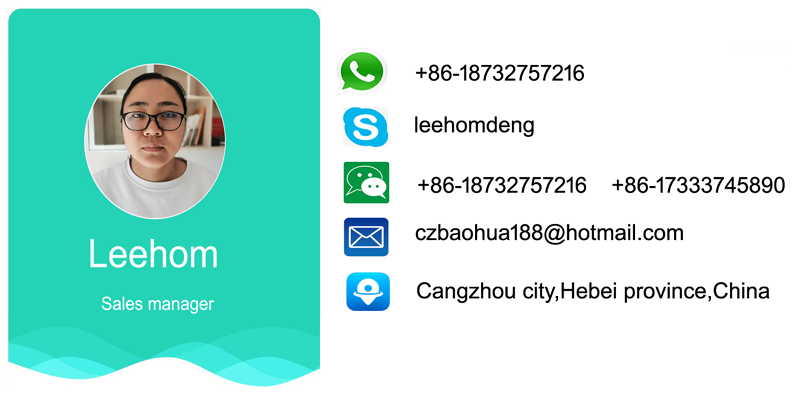

1.Service:

a.If buyers visit our factory and check the machine, we will teach you how to install and use the

machine,

b.Without visiting, we will send you user manual and video to teach you to install and operate.

c.One year guarantee for whole machine.

d.24 hours technical support by email or calling

2.How to visit your company?

a.Fly to Beijing airport:By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can

pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),

then we can pick up you.

3.Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport.

4.You are trade company or factory?

we have own factory.

5.What can you do if the machine broken?

The buyer send us the photos or videos. We will let our engineer to check and provide professional suggestions. If it needs change parts, we will send the new parts only collect cost fee.