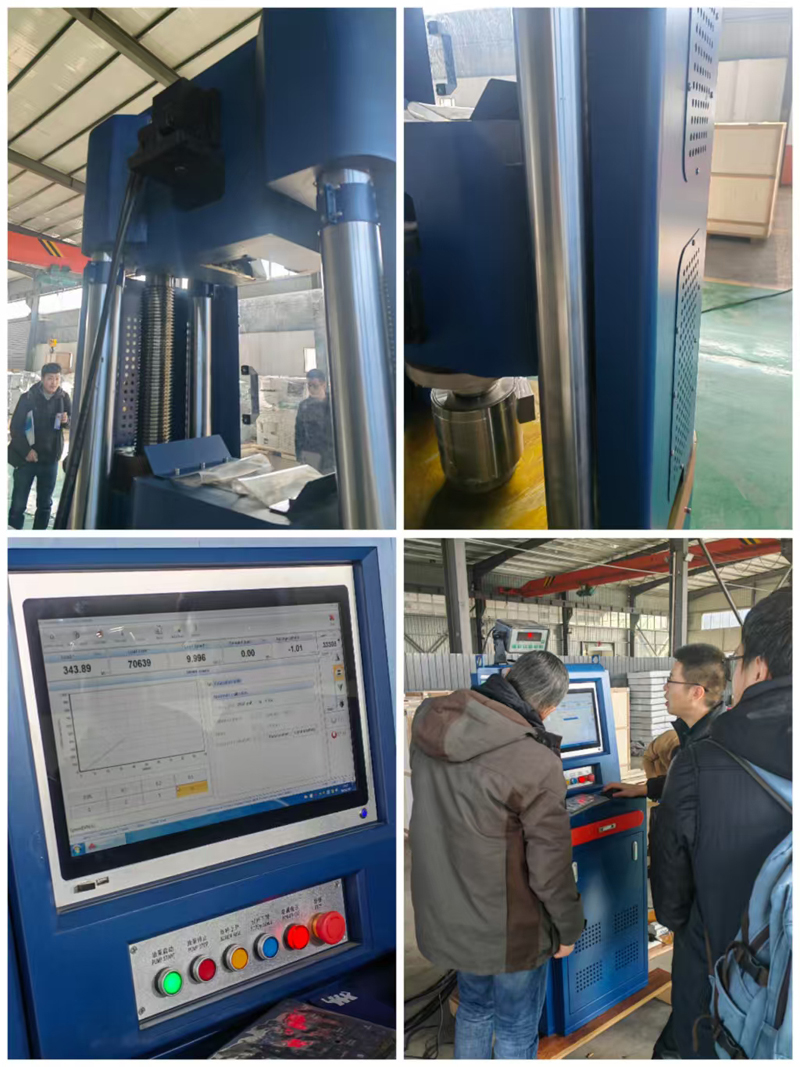

Mongolia customer orders hydraulic Universal Testing Machine

WES series “MEMS Servo Universal Material Testing Machine” adopts hydraulic power source drive, electro-hydraulic servo control technology, Computer data automatic collection and processing, host and control cabinet separate design, with easy operation, stable and reliable work, accurate test accuracy, one-click operation loading speed is stable, can meet the national provisions on metal tensile test in the standard test, can also be in accordance with other standards for different materials or products tensile, compression, bending, shearing and other types of tests. The testing machine and accessories meet: GB/T228, GB/T2611, GB/T16826 standard requirements.

|

Model

|

WE-100B

|

WE-300B

|

WE-600B

|

WE-1000B

|

|

Max. test force

|

100KN

|

300KN

|

600KN

|

1000KN

|

|

Lifting speed of middle beam

|

240 mm/min

|

240 mm/min

|

240 mm/min

|

300 mm/min

|

|

Max. spacing of compression surfaces

|

500 mm

|

600mm

|

600 mm

|

600mm

|

|

Max.stretch spacing

|

600 mm

|

700mm

|

700 mm

|

700mm

|

|

Effective distance between two columns

|

380mm

|

380mm

|

375mm

|

455mm

|

|

Piston stroke

|

200 mm

|

200mm

|

200 mm

|

200mm

|

|

Max. speed of piston movement

|

100 mm/min

|

120mm/min

|

120 mm/min

|

100mm/min

|

|

Round sample clamping diameter

|

Φ6 mm –Φ22mm

|

Φ10 mm –Φ32mm

|

Φ13mm-Φ40mm

|

Φ14 mm –Φ45mm

|

|

Clamping thickness of flat specimen

|

0 mm -15mm

|

0 mm -20mm

|

0 mm -20mm

|

0 mm -40mm

|

|

Max. distance of fulcrum in bending test

|

300 mm

|

300mm

|

300 mm

|

300mm

|

|

Up and down plate size

|

Φ110mm

|

Φ150mm

|

Φ200mm

|

Φ225mm

|

|

Overall dimension

|

800x620x1850mm

|

800x620x1870 mm

|

800x620x1900mm

|

900x700x2250 mm

|

|

Dimensions of oil source tank

|

550x500x1200 mm

|

550x500x1200 mm

|

550x500x1200mm

|

550x500x1200 mm

|

|

Power

|

1.1KW

|

1.8KW

|

2.2KW

|

2.2KW

|

|

Weight

|

1500KG

|

1600KG

|

1900KG

|

2750KG

|

Hydraulic Universal Testing Machine: Overview

In the field of materials science and engineering, the Hydraulic Universal Materials Testing Machine (HUMTM) is an essential tool for evaluating the mechanical properties of a wide range of materials. This advanced equipment is designed to perform a wide range of tests, including tension, compression, bending and shear tests, making it an essential asset for laboratories, research institutions and manufacturing plants.

What is a hydraulic universal materials testing machine?

The Hydraulic Universal Testing Machine is a versatile testing device that uses hydraulic power to apply controlled loads to materials. The machine is equipped with a hydraulic system that generates precise forces to accurately measure the behavior of materials under different loading conditions. The versatility of the HUMTM allows them to test metals, plastics, composites and even biomaterials, making them an indispensable tool for various industries such as aerospace, automotive, construction and biomedical.

Main features and components

The design of a hydraulic universal testing machine usually includes several key components:

1. Hydraulic System: The hydraulic system is the heart of the HUMTM and consists of pumps, cylinders and valves that work together to generate and control the force applied to the sample. The system can adjust the load smoothly and precisely, ensuring accurate test results.

2. Load Frame: The load frame provides the structural integrity required to withstand the forces applied during testing. It is designed to minimize deflection and maintain alignment, ensuring that the load is applied evenly to the specimen.

3. Control Systems: Modern HUMTMs are equipped with advanced control systems that automate test procedures. These systems can be programmed to perform specific tests, record data, and generate reports, increasing efficiency and accuracy.

4. Grips and Fixtures: In order to hold the test specimen securely in place, a variety of grips and fixtures are used. These components are designed to accommodate materials of different shapes and sizes, ensuring that the load is applied correctly.

5. Data Acquisition System: The data acquisition system collects and analyzes data during the test. It provides real-time feedback on the material’s response to the applied load, allowing for detailed analysis of mechanical properties such as yield strength, tensile strength, elongation, and elastic modulus.

Application of hydraulic universal material testing machine

The applications for HUMTM are wide and varied. In the construction industry, they are used to test the strength of concrete and steel, ensuring that materials meet safety standards. In the automotive industry, HUMTM assess how parts perform under stress, helping to develop safer vehicles. And in the aerospace industry, these machines are essential for testing materials that must withstand extreme conditions.

In addition, HUMTM plays an important role in research and development. Engineers and scientists use these machines to explore new materials and improve existing ones, driving innovation in many fields.

The Hydraulic Universal Testing Machine is an essential tool for evaluating material properties. Its ability to accurately and reliably perform a wide range of tests is invaluable to a wide range of industries. As technology continues to advance, the capabilities of the HUMTM are expected to expand, further enhancing its role in materials testing and helping to develop safer, more efficient products. Whether in the laboratory or in a manufacturing environment, the HUMTM remains a cornerstone of materials testing, ensuring the materials we rely on meet the highest standards of quality and performance.

Post time: Feb-26-2025