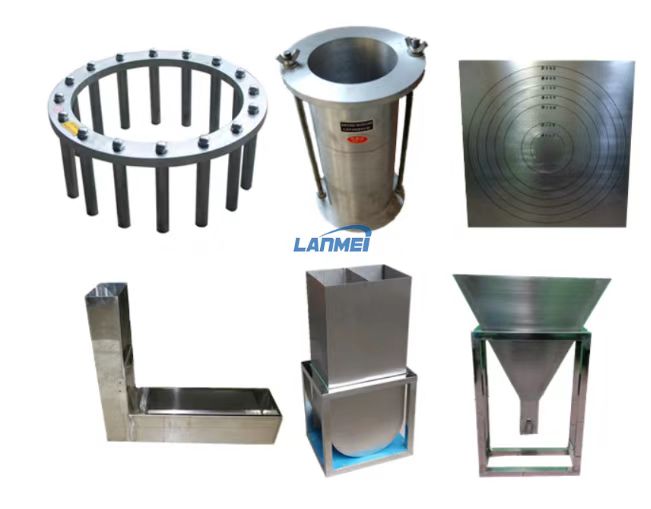

Self- Compacting Cement Concrete Slump Flow test Apparatus

Self- Compacting Cement Concrete Slump Flow test Apparatus

Plate thickness:3.0mm,2.0mm,1.3mm

Size:1M*1M,1.2M*1.2MM,0.8M*0.8M Customizable

Material :Stainless steel

Self-compacting cement concrete slump tester

Self-compacting cement concrete (SCCC) has revolutionized the construction industry by providing a solution that improves workability and reduces labor costs. One of the key aspects of ensuring the quality of SCCC is the slump flow test, which measures the material’s ability to flow and fill a mold without the need for mechanical vibration. The slump flow tester is an important tool for engineers and construction professionals to evaluate the performance of self-compacting concrete.

A slump flow tester usually consists of a conical mold, a base plate, and a measuring device. The process begins by filling the mold with a self-compacting concrete mix. Once filled, the mold is lifted vertically to allow the concrete to flow freely. The diameter of the spread concrete is then measured to quantitatively assess its flowability. This measurement is crucial because it indicates whether the concrete is able to adequately fill complex shapes and reach all areas of the structure without leaving voids.

The importance of slump flow testing cannot be overstated. Not only does it help determine the workability of concrete, but it is also an indicator of its overall quality. A good performing self-compacting concrete mix should have a slump flow diameter that meets specified standards, ensuring it can be effectively used in a variety of applications, from precast elements to heavy reinforced structures.

In summary, the SCC slump flow tester is an essential instrument for the construction industry. By providing a reliable method to assess the flow properties of SCC, it helps ensure projects are completed efficiently and to the highest quality standards. As the demand for innovative building materials continues to grow, this testing equipment will continue to play a key role in maintaining the integrity and performance of modern concrete solutions.