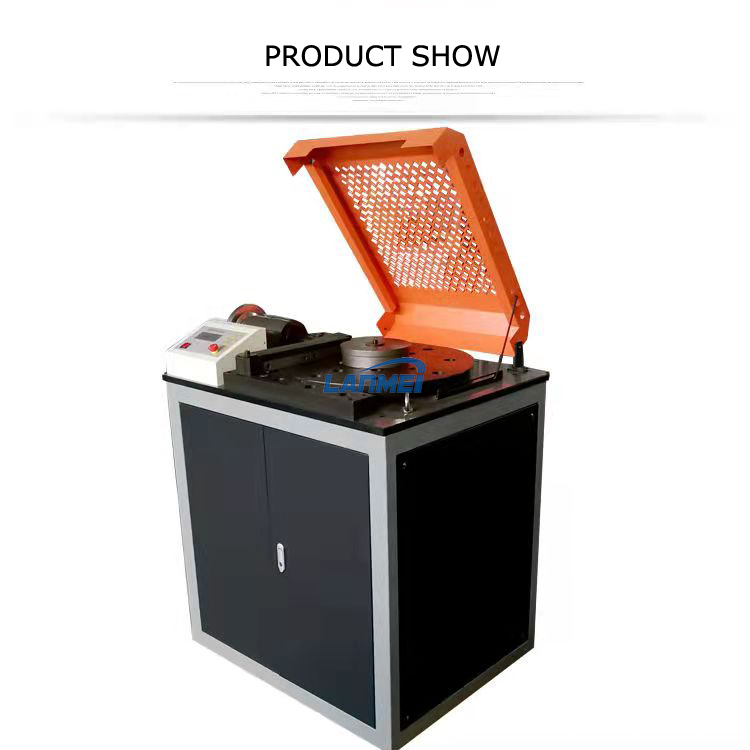

Universal Materials Testing Machine

Universal Materials Testing Machine

WES series “MEMS Servo Universal Material Testing Machine” adopts hydraulic power source drive, electro-hydraulic servo control technology, Computer data automatic collection and processing, host and control cabinet separate design, with easy operation, stable and reliable work, accurate test accuracy, one-click operation loading speed is stable, can meet the national provisions on metal tensile test in the standard test, can also be in accordance with other standards for different materials or products tensile, compression, bending, shearing and other types of tests. The testing machine and accessories meet: GB/T228, GB/T2611, GB/T16826 standard requirements.

**Introduction to Hydraulic Servo Universal Testing Machine: Perfect Combination of Precision and Performance**

In the ever-evolving world of materials testing, the servo-hydraulic universal testing machine stands out as a beacon of innovation and reliability. Designed for both laboratory and industrial applications, this state-of-the-art testing machine is engineered to evaluate the mechanical properties of a wide range of materials with unmatched precision and efficiency. Whether you are in the field of research, quality control or product development, this machine is your ultimate partner in ensuring the integrity and performance of your materials.

**Unrivaled Precision and Control**

At the heart of the Servo Hydraulic Universal Testing Machine is its advanced servo-hydraulic system, which provides excellent control over the testing process. This technology enables precise load application and displacement measurement, ensuring that every test is performed with the highest precision. The machine’s load capacity can be tailored to your specific needs, with the ability to test a wide range of materials from metals and plastics to composites and ceramics.

The intuitive control interface allows the operator to easily set parameters and monitor the test process in real time. With programmable test sequences and customizable settings, you can easily perform tension, compression, flexure and shear tests. The machine is capable of performing both static and dynamic tests, making it a versatile tool for any laboratory.

**ROUGH DESIGN**

The Servo Hydraulic Universal Testing Machine is manufactured using high-quality materials and components to withstand the rigors of daily use. Its sturdy frame ensures stability during testing, while the hydraulic system is designed to be durable and low-maintenance. This durability not only extends the life of the machine, but also guarantees consistent performance over the long term, making it a smart investment for any organization.

**FULL DATA ANALYSIS**

In today’s data-driven world, the ability to analyze and interpret test results is critical. Servohydraulic universal testing machines are equipped with advanced software that facilitates comprehensive data collection and analysis. Users can easily generate detailed reports, graphs, and charts that provide insight into material behavior under a variety of conditions. This capability not only enhances the testing process, but also helps make informed decisions about material selection and product design.

Safety first

Safety is paramount in any testing environment, and the Servo Hydraulic Universal Testing Machine has been designed with this in mind. The machine is equipped with a variety of safety features, including an emergency stop function and overload protection, to ensure that the operator has a safe testing experience. The ergonomic design also promotes safe handling and operation, reducing the risk of accidents in the laboratory.

**Multiple Apps**

The versatility of the Servo Hydraulic Universal Testing Machine makes it suitable for a wide range of applications across a wide range of industries. From aerospace and automotive to construction and manufacturing, this machine is an essential tool for engineers, researchers and quality control professionals. Its ability to test different materials and perform various types of tests makes it a valuable asset to any materials testing laboratory.

**In summary**

In short, the servohydraulic universal testing machine is a cutting-edge solution for all your material testing needs. With its precision, durability and advanced data analysis capabilities, it enables users to conduct comprehensive and reliable testing to drive product innovation and quality. Invest in the future of material testing and enhance your laboratory’s capabilities with a servohydraulic universal testing machine – the perfect combination of precision and performance.

|

Model

|

WE-100B

|

WE-300B

|

WE-600B

|

WE-1000B

|

|

Max. test force

|

100KN

|

300KN

|

600KN

|

1000KN

|

|

Lifting speed of middle beam

|

240 mm/min

|

240 mm/min

|

240 mm/min

|

300 mm/min

|

|

Max. spacing of compression surfaces

|

500 mm

|

600mm

|

600 mm

|

600mm

|

|

Max.stretch spacing

|

600 mm

|

700mm

|

700 mm

|

700mm

|

|

Effective distance between two columns

|

380mm

|

380mm

|

375mm

|

455mm

|

|

Piston stroke

|

200 mm

|

200mm

|

200 mm

|

200mm

|

|

Max. speed of piston movement

|

100 mm/min

|

120mm/min

|

120 mm/min

|

100mm/min

|

|

Round sample clamping diameter

|

Φ6 mm –Φ22mm

|

Φ10 mm –Φ32mm

|

Φ13mm-Φ40mm

|

Φ14 mm –Φ45mm

|

|

Clamping thickness of flat specimen

|

0 mm -15mm

|

0 mm -20mm

|

0 mm -20mm

|

0 mm -40mm

|

|

Max. distance of fulcrum in bending test

|

300 mm

|

300mm

|

300 mm

|

300mm

|

|

Up and down plate size

|

Φ110mm

|

Φ150mm

|

Φ200mm

|

Φ225mm

|

|

Overall dimension

|

800x620x1850mm

|

800x620x1870 mm

|

800x620x1900mm

|

900x700x2250 mm

|

|

Dimensions of oil source tank

|

550x500x1200 mm

|

550x500x1200 mm

|

550x500x1200mm

|

550x500x1200 mm

|

|

Power

|

1.1KW

|

1.8KW

|

2.2KW

|

2.2KW

|

|

Weight

|

1500KG

|

1600KG

|

1900KG

|

2750KG

|